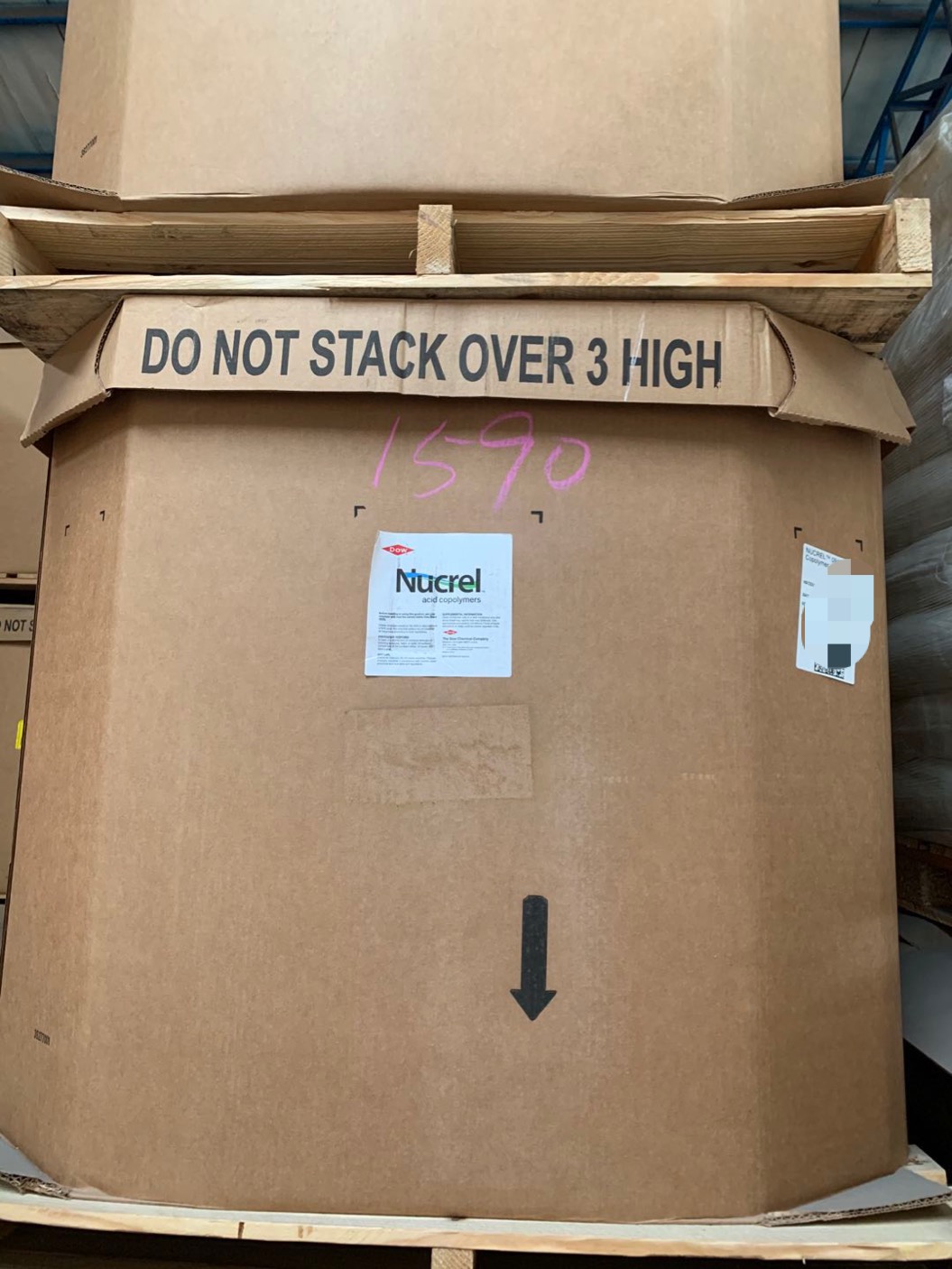

美国杜邦Nucrel® 0910 是一种 乙烯甲基丙烯酸 (EMAA) 材料。 可在 北美洲、非洲和中东、拉丁美洲、欧洲或亚太地区 中获得,具有低温柔软,抗化学性,透明,相容性好,与金属箔的粘合力易于溶解,用于自粘型复合带,铝塑复合带等加工方式为共挤出成型或挤出。

美国杜邦Nucrel® 0910 是一种 乙烯甲基丙烯酸 (EMAA) 材料。 可在 北美洲、非洲和中东、拉丁美洲、欧洲或亚太地区 中获得,具有低温柔软,抗化学性,透明,相容性好,与金属箔的粘合力易于溶解,用于自粘型复合带,铝塑复合带等加工方式为共挤出成型或挤出。

Nucrel® 0910 和典型应用: 食品接触应用

比重 0.930g/cm³ ASTM D792

熔流率 (190°C/2.16 kg) 10g/10 min ASTM D1238

EMAA综合性能表现

EMAA材料的熔点,主导了材料的热性能,可以将EMAA划分为不同温度类型的应用,即高温胶、中温胶、低温胶能。

EMAA广泛应用于包装、粉末涂层、粘合剂、热熔胶、密封材料、水性溶剂等方面,下面简要介绍:

1、聚合物改性

2、热熔性粘合剂和密封剂

3、挠性软管和普通管子

4、层压片材

5、多层薄膜、注塑和挤压零件

6、电线和电缆混合料。

EMAA特性备注:

优良的热稳定性,颜料着色力优异,对各种基材都具有粘结力,这些基材包括金属、聚烯烃、纤维素、聚酯、聚碳酸酯、聚偏二氯乙稀(PVDC)、玻璃和金属箔等。主要应用于包装、粉末涂层、粘合剂、热熔胶、密封材料、水性溶剂,环保降解材料等方面。

供应EMAA美国杜邦 供应EMAA 0910,9925,960,599,699,6100,3004.3440,3460, 具有低温柔软,抗化学性,透明,相容性好,易于溶解,用于自粘型复合带,铝塑复合带等